EagerLED consistently upholds strict quality control measures, conducting thorough tests on brightness, color consistency, power stability, and accessories to ensure every product meets high-quality standards.

Quality Control Before Production

EagerLED is committed to ensuring exceptional performance and reliability of LED displays right from the start. Prior to production, we rigorously inspect all raw materials, confirm the viability of technical solutions, and verify that all equipment is operating correctly.

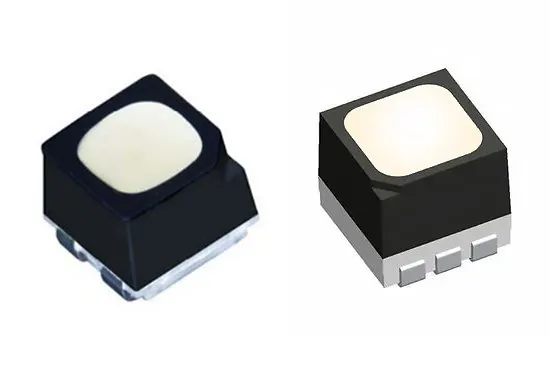

High-quality raw materials

EagerLED selects high-grade raw materials, including dependable LED lamp beads, durable PCB boards, stable driver ICs, and quality connecting wires, to ensure product reliability and performance.

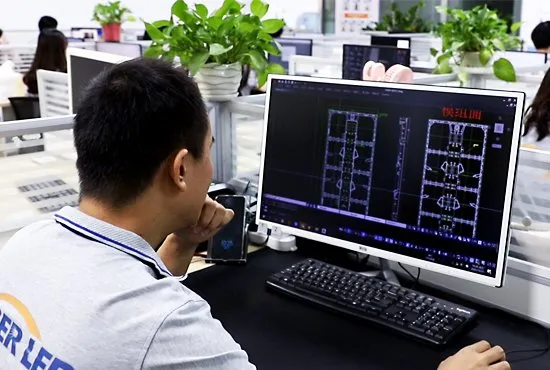

Develop feasible solutions

We engage in thorough communication with customers to develop practical and tailored solutions based on their specific requirements, while also performing technical validation, cost estimation, and risk evaluation.

Confirm production details

Verify every stage of the production process, including the workflow and equipment setup, to ensure that all steps run smoothly and as planned.

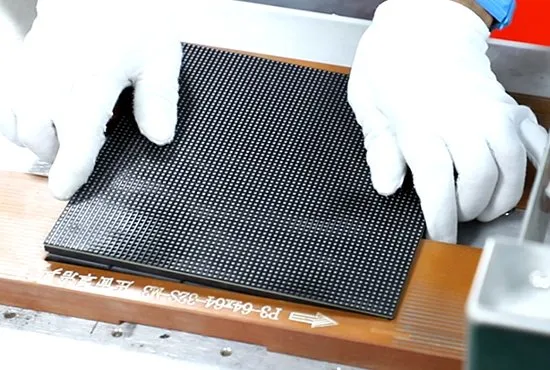

Quality Control Of LED Modules

EagerLED highly prioritizes the control of LED module production by adhering to top industry standards, employing advanced automated machinery, and enforcing rigorous testing procedures to guarantee product quality.

Dust-free workshop

EagerLED’s production workshop features a high-efficiency air filtration system, maintaining cleanliness at ISO Class 5 or higher, with regular cleaning and disinfection routines in place.

Advanced production equipment

EagerLED’s production facility is fully equipped with specialized machinery for LED chip processing, packaging, testing, assembly, and debugging.

LED module comprehensive test

To ensure quality and performance, we conduct comprehensive testing of the LED display module, including appearance, circuitry, soldering, and overall functionality.

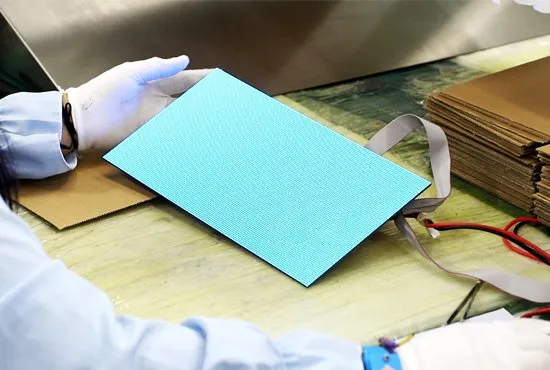

LED Module Lighting Test

To verify that the LED module meets the desired standards for brightness, color accuracy, and energy efficiency, a professional lighting test is essential.

Aging Test for LED Modules

EagerLED replicates real-world application environments to identify and eliminate modules with unstable performance or hidden defects, enhancing product quality and ensuring long-term reliability.

Comprehensive aging test

We perform dedicated aging tests not only on individual LED modules but also on the complete LED display to ensure users receive long-lasting and reliable products.

Quality Control Of Packaging

EagerLED follows a strict packaging plan, emphasizing professional design and robust protection to prevent damage during transit, ensuring customers receive their LED displays in perfect condition.

Wooden box

For large or heavy LED displays, wooden crates are a preferred option because of their strong structure and load-bearing ability. While more cost-effective than aviation cases, wooden crates offer less durability.

Air Box

EagerLED air boxes provide superior compression resistance, impact protection, and waterproofing. Equipped with PU wheels on the bottom for easy mobility, they are primarily used for rental LED displays.

EagerLED implements a rigorous quality control system throughout the entire production process to guarantee that every product meets high standards and fulfills customer requirements and expectations.