NovaStar TU40 Pro Specifications: Everything You Need to Know

2026-02-26T03:52:39+00:00February 26, 2026|Tags: FAQs NovaStar|

Colorlight X8m Ultra-4K LED Video Processor Review: Performance, Features & Advantages

2026-02-02T03:18:55+00:00February 13, 2026|Tags: FAQs Colorlight|

HUIDU HD-VP620 LED Display All-In-One Video Processor

2026-02-02T03:02:40+00:00February 2, 2026|Tags: FAQs HuiDu|

- 1. Что такое технология светодиодных дисплеев MiP?

- 2. Процесс производства светодиодных дисплеев MiP

- 3. Преимущества светодиодных дисплеев MiP

- 4.MiP LED против SMD против COB против IMD

- 5.Применение светодиодных дисплеев MiP

- 6. Будущее технологии светодиодных дисплеев MiP

- 7.Conclusion

- Получить ценовое предложение бесплатно

LED display technology moves fast. Every few years a new packaging method promises brighter visuals, tighter pixel pitch, lower power, and better reliability. A few seasons ago the conversation was all SMD (surface-mounted device). Then COB (chip-on-board) made waves for ultra-fine pitch and robustness. Now a new balance has arrived: the MiP LED display.

If you’re planning digital signage, stage backgrounds, retail walls, or corporate lobby screens, you’ve probably heard the term and wondered what it really means. MiP LED display technology, short for “Mini LED in Package”, borrows what works from previous approaches, avoids their weak spots, and aims squarely at real-world deployment: high resolution, high reliability, and sensible cost.

In this guide we’ll unpack what is MiP LED display technology.

Table of Content

- 1. Что такое технология светодиодных дисплеев MiP?

- 2. Процесс производства светодиодных дисплеев MiP

- 3. Преимущества светодиодных дисплеев MiP

- 4.MiP LED против SMD против COB против IMD

- 5.Применение светодиодных дисплеев MiP

- 6. Будущее технологии светодиодных дисплеев MiP

- 7.Conclusion

- Получить ценовое предложение бесплатно

1.What Is MiP LED Display Technology?

Let’s start at the foundation: what is MiP LED display technology? MiP stands for Mini LED in Package. Instead of bonding a bare die directly to a substrate (as in COB) or mounting a relatively larger LED package on a PCB (as in SMD), the MiP approach encapsulates mini-LED chips into small, rugged packages that are purpose-built for fine-pitch video walls.

Here’s why that matters. Traditional SMD LED display technology is proven, scalable, and cost-effective, but as pixel pitch gets tighter (think sub-2.0 mm, sub-1.5 mm, even sub-1.0 mm), SMD begins to strain, packages are bulkier, uniformity gets harder, and accidental knocks can damage protruding diodes. COB answered those pain points by covering the bare chips with protective resin, delivering smooth surfaces and superb uniformity. The trade-offs? More specialized manufacturing, tougher repair, and typically higher costs.

MiP LED display technology seeks the middle ground. Each mini-LED is individually packaged, small enough for ultra-fine pitch, robust enough to survive handling, and modular enough to assemble with existing SMD-style equipment. That makes it easier to scale production, manage inventories, and maintain screens in the field. In practice, a MiP LED display gives you the refined look of fine-pitch COB, with the serviceability and supply-chain familiarity of SMD.

So when you see “MiP,” think: high-resolution, durable, and maintainable. It’s still LED display technology at the core, just a smarter package for today’s pixel-tight, always-on installations.

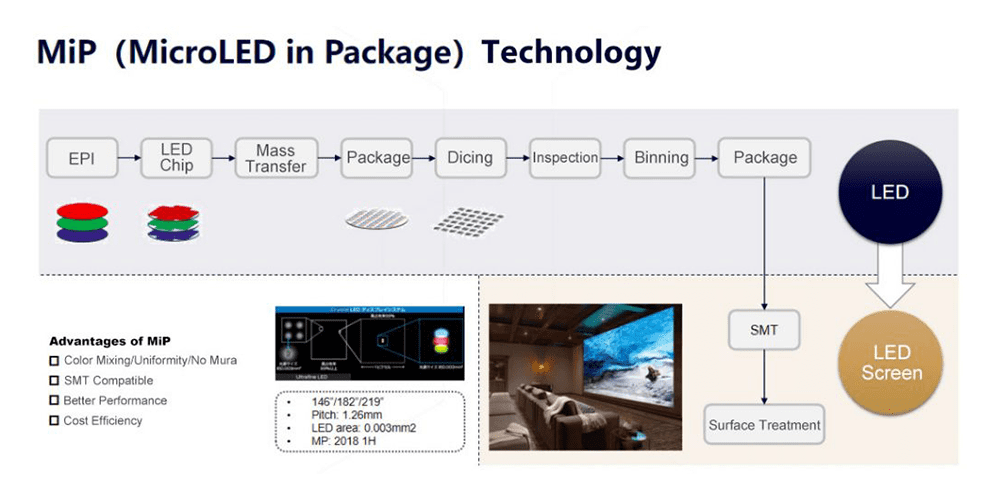

2.The Manufacturing Process of MiP LED Displays

The MiP LED display process blends the best of proven SMD workflows with the precision packaging of next-gen mini-LED.

1) Material selection & package design

Engineering teams start by choosing mini-LED dies for luminous efficacy, wavelength stability, and lifetime. The “MiP” part, Mini LED in Package, means each die is encapsulated in a compact, rugged housing. The package recipe matters: the lens geometry, phosphor mix, and encapsulant all influence brightness, color uniformity, and anti-static behavior. This is a foundational reason MiP LED technology achieves fine pixel pitch without the fragility that can plague legacy SMD at sub-1.5 mm.

2) Encapsulation (the MiP step)

Dies are binned for color and brightness, then encapsulated into packages small enough for high-resolution assemblies. Compared with COB’s resin-top approach, a MiP LED display keeps every emitter mechanically protected yet individually addressable, which becomes essential for long-term maintainability and field repair.

3) Cutting, sorting & binning

After packaging, LEDs are cut from wafers/tapes and graded (“binned”) to tight tolerances. This pre-sorting is the quiet hero of the MiP LED display process, it reduces cabinet-to-cabinet variance and enables factory-level calibration to hold over time. Good binning is what keeps whites white and gradients smooth on a wall built from hundreds of tiles.

4) SMT module assembly

One practical advantage of MiP LED display technology is compatibility with mature SMT lines. Packages place onto PCBs like familiar SMD, then pass through reflow. That reuse of infrastructure shortens lead times, stabilizes supply, and helps keep MiP LED display pricing realistic at fine pitch.

5) Protection, power & thermal design

Manufacturers add conformal coatings or matte micro-textures to fight dust, moisture, glare, and ESD. Under the surface, copper pours, thermal vias, and heatsinks wick heat from dense pixel fields, the hidden work that preserves color stability and lifetime. Power is architected to avoid voltage drop and banding; clean wiring and balanced strings prevent local hotspots that can prematurely age LEDs.

6) Calibration, QA & traceability

Before shipment, modules and cabinets undergo brightness/white-point calibration (often to D65), low-gray linearity checks, aging tests, and refresh-rate validation for camera-friendliness. The best lines serialize every module, embedding QR/Datamatrix IDs tied to bin, batch, and test data. If a field anomaly appears, traceability lets teams isolate a batch and resolve it quickly, another tangible benefit of MiP LED display thinking.

3.Advantages of MiP LED Displays

When buyers weigh MiP LED display advantages, five themes consistently tip the decision: visual performance, durability, serviceability, ecosystem fit, and total cost of ownership. Together, they explain why MiP LED display technology is becoming many teams’ default for small-pitch indoor walls.

3.1 High-resolution visuals without fragile trade-offs

A MiP LED display is built for close-range viewing, retail, boardrooms, control rooms, studios. Tight binning plus package-level optics deliver crisp text, smooth gradients, and stable color at low luminance. You get much of COB’s polish without the fully resin-sealed surface, which can complicate rework.

3.2 Real-world durability (dust, moisture, ESD, handling)

Because each emitter is in a rugged package, MiP is tougher than protruding SMD diodes and less fussy to handle on site. Anti-static design and protective coatings resist common failure modes in LED display technology deployments, especially where installers, stagehands, or visitors may interact with the wall.

3.3 Easier maintenance & faster SLAs

Serviceability is the sleeper benefit of MiP LED display. If a pixel fails, technicians can rework an individual package or swap a tile using bench methods they already know. You don’t need to retire a whole module for a single point defect. That keeps spare inventories lean and makes SLA commitments realistic.

3.4 Efficiency, heat, and operating comfort

At the same nit target, packaged mini-LEDs often run more efficiently than older, larger SMD packages at similar pitches. Less waste heat means quieter fans (or passive cooling) and longer component life. For meeting rooms and control centers, that thermal headroom also preserves color stability over long, always-on days.

3.5 Ecosystem compatibility & scale

Because the MiP LED display process lives on SMT lines, manufacturers can scale production without reinventing factories. Integrators can standardize on tile sizes, power schemes, and controllers they already deploy. That ecosystem fit shortens projects, simplifies training, and stabilizes pricing across multi-site rollouts of commercial MiP LED displays.

3.6 Refined HDR and camera-friendly behavior

For broadcast backdrops, virtual production, or esports stages, refresh-rate options and low-gray control matter. Properly tuned MiP LED display technology preserves subtle shadow detail and avoids banding, while higher refresh plays nicely with shutters on set, sharp motion without color compromise.

3.7 TCO, today and tomorrow

MiP narrows the visual gap with COB while holding onto SMD-like serviceability. Over a wall’s life, that combination of value pricing, lower energy, and faster repairs usually wins the TCO race. It’s why procurement teams increasingly cite MiP LED display advantages when standardizing a spec for fine-pitch indoor projects.

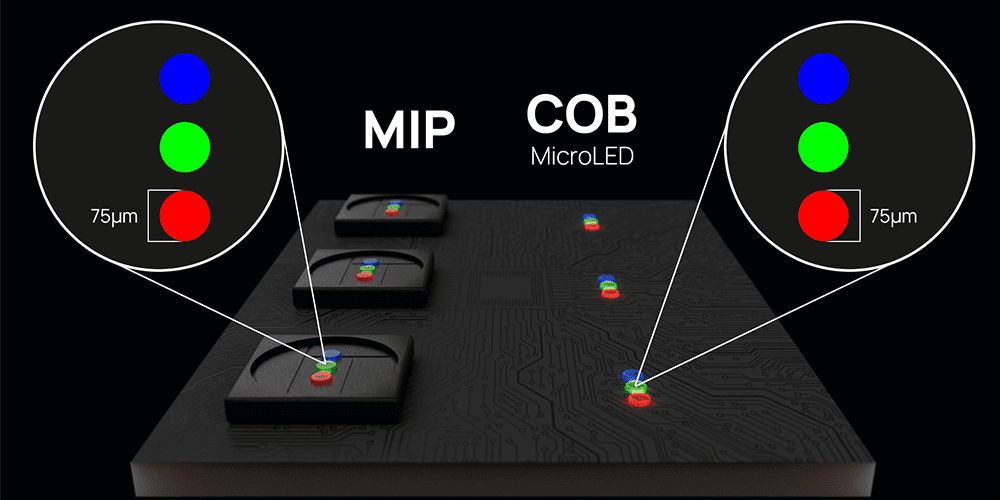

4.MiP LED vs SMD vs COB vs IMD

Comparisons are where buying decisions crystallize. Here’s a straight, procurement-oriented look at MiP LED vs SMD, MiP LED vs COB, and MiP LED vs IMD, plus a simple framework to choose the right path for your venue and content.

4.1 MiP LED vs SMD

Where SMD still fits: At pixel pitches ≥2.5 mm with budget pressure, classic SMD is proven and economical.

Why MiP pulls ahead: As you push to sub-1.5 mm, SMD’s bulkier diodes become harder to protect and to uniformize. A MiP LED display delivers tighter pitch, better mechanical resilience, and cleaner low-gray behavior, especially important for UI text, dashboards, and camera work.

Service reality: Both are serviceable, but MiP’s smaller, protected package reduces incidental damage during install/service, an operational win for busy sites.

4.2 MiP LED vs COB

Visuals: COB’s glassy uniformity and deep black are superb, particularly at micro-pitch. MiP LED display technology gets very close for most indoor use cases, particularly in the 0.9–1.8 mm band.

Durability & handling: COB’s resin face is touch-friendly; MiP’s rugged packages handle transit and staging well.

Service & risk: COB module rework can be specialized and time-consuming. MiP supports package-level rework or quick tile swaps on familiar benches, less downtime, fewer specialized spares.

Cost & availability: COB often commands premium pricing and longer lead times. MiP leverages SMT lines, improving availability and stabilizing price.

Bottom line: If you need the absolute smoothest surface and accept premium pricing, COB is king. If you want 90–95% of that visual polish with easier service, shorter lead times, and friendlier budgets, MiP LED vs COB favors MiP.

4.3 MiP LED vs IMD

Architecture: IMD (Integrated Matrix Device) groups multiple chips into one package to drive ultra-dense pitches. MiP keeps emitters individually packaged yet tiny, emphasizing SMT compatibility and straightforward field repair.

Failure modes: With IMD, a single package fault may affect a larger pixel cluster. With MiP LED, a single package swap can clear a defect without visible “block” artifacts.

Adoption path: MiP’s workflow continuity appeals to manufacturers and integrators standardizing global rollouts of commercial MiP LED displays.

Decision cue: If your operations prioritize maintainability, familiar tooling, and predictable spares, MiP LED vs IMD generally tilts MiP.

5.Applications of MiP LED Displays

The most persuasive argument for a MiP LED display is how naturally it drops into today’s venues and workflows. Here are the application zones where the benefits of MiP LED display are most obvious:

5.1 Retail & Showrooms

Brand walls, window displays, and product launch corners need fine-pitch clarity at arm’s-length viewing. A commercial MiP LED display delivers luxury-grade visuals, true color, deep contrast, readable micro-type, without the fragility and service complexity that can derail in-store deployments.

5.2 Corporate & Education

Boardrooms, training centers, lecture halls, and lobbies call for indoor MiP LED displays that stay sharp for spreadsheets, dashboards, and high-detail content. The added durability helps with frequent use, while the MiP LED display process supports consistent scaling from a single wall to a multi-floor campus.

5.3 Stage Backgrounds & Events

Event pros crave a wall that’s bright, precise, and road-tough. MiP LED display technology offers the pixel density artists want with the handling resilience crews need. It’s also serviceable between shows, making it practical for rental fleets and touring productions.

5.4 Control Rooms & Command Centers

Operators sit close for hours. Visual fatigue is real. A fine-pitch MiP LED display provides uniform brightness and color, clear tiny text, and minimized pixel “sparkle,” improving comfort and accuracy on long shifts.

5.5 Future Outdoor Concepts

Most MiP LED display applications today are indoor, but the package’s anti-static, moisture, and dust resistance hint at future outdoor rollouts, especially in covered or semi-exposed environments. As MiP LED technology trends continue, expect ruggedized versions designed for sunlight readability and weather cycles.

No matter the venue, the through-line is the same: small pitch, high resolution, real durability, and easier service. That’s the MiP recipe.

6.The Future of MiP LED Display Technology

1) Convergence with MicroLED & Advanced Transfers

As microLED die shrink and mass-transfer processes mature, MiP LED technology can ride that progress, packaging ever-smaller chips with ever-tighter tolerances. Expect denser walls, improved HDR, and even better efficiency without abandoning serviceability.

2) Smarter System Integration

The wall is one piece; the system matters too. Expect MiP LED display technology to pair with higher-bit-depth controllers, AI-assisted calibration, adaptive brightness, and cloud device management. That keeps visuals consistent and operating costs predictable, especially across multi-site networks.

3) Healthy Competition with COB Evolution

COB won’t sit still. Resin formulations, surface micro-structures, and black matrix improvements will push contrast and robustness further. The upside for buyers: MiP LED vs COB will remain a value equation rather than a forced choice. As COB gets better, MiP will keep closing performance gaps while guarding its advantages in cost and field repair.

Overlay those forces with MiP LED technology trends, more retail rollouts, more corporate video walls, immersive stage designs, and you get a clear signal: MiP LED displays are on a long, steady climb from “promising” to “default” for fine-pitch indoor projects.

7.Conclusion

If you strip away the buzzwords, the MiP LED display proposition is refreshingly practical:

- Visualsgood enough for demanding fine-pitch content,

- Hardwaredurable enough for frequent use and handling,

- Processescompatible with existing SMT lines,

- Servicesimple enough to keep downtime low, and

- Costscontrolled enough to scale across a portfolio, not just a flagship site.

That blend is why MiP LED display technology feels like the right answer to 2025’s question: “How do we deploy ultra-sharp video walls without premium headaches?”

If your roadmap includes upgrading LED display technology across retail, corporate, education, events, or control rooms, put MiP LED display on the shortlist. Its advantages, from durability to maintainability to cost balance, make it a smart standard for modern, high-resolution walls. And as MiP LED technology trends push the category forward, you’ll have a platform that evolves gracefully rather than locking you into niche processes.

That’s the promise of MiP: the benefits of MiP LED display without the usual trade-offs, and a path into the future of MiP LED display that stays practical, scalable, and ready for whatever your content dreams up next.

Novastar MCTRL4K – The Ultimate LED Display Controller Guide

Novastar MCTRL4K – The Ultimate LED Display Controller Guide NovaStar Viplex Handy: Manual Download Guide & FAQs

NovaStar Viplex Handy: Manual Download Guide & FAQs